Synopsis

The global acknowledgment and recognition for sustainable industrial process has necessitated the review of existing systems and processes. This article introduces the innovative business models of Chemicals Leasing (ChL) and Chemical Management services (CMS) from a Management Accountant’s perspective. Their effectiveness in achieving SDG goals make them attractive for all those who are exploring ways and means for transforming business into sustainable modes.

An overview of Chemical Leasing (ChL) and Chemical Management Service (CMS)

Chemical Leasing (ChL) is a methodology originally identified by UNIDO for achieving a service oriented business model which establishes a partnership between the chemical supplier and user for reducing the adverse environmental impact arising from the use of industrial chemicals. The supplier no longer has to worry about the quantum of material sold as the payment is linked to the extent of functions performed and it is measured based on the outcomes achieved. It is a strategic partnership between the supplier and the consumer aimed at reducing chemical consumption and results in enhanced performances, reduction in costs based on economic and environmental benefits. The shift in focus from the quantum to the outcome achieved for effecting payments does not lead to adverse economic impact on the supplier or consumer while achieving environmental benefits. UNIDO and European countries like Austria, Germany, and Switzerland have been promoting this business model as it helps in attaining sustainability in the Chemical industry.

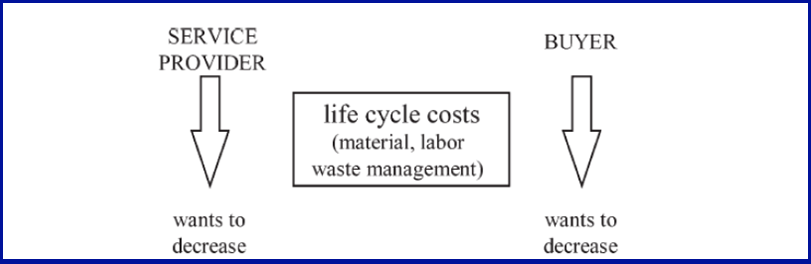

(fig.1 Conflicting Objectives in a traditional supplier – customer model)

(fig. 2 Aligned Objectives in a servicized chemical supply relationship)

Chemical Leasing is defined as a service-oriented business model that shifts the focus from increasing sales volume of chemicals, toward a value-added approach. The producer mainly sells the functions performed by the chemical, and functional units are the main basis for payment. Within chemical leasing business models, the responsibility of the producer and service provider is extended and may include the management of the entire life cycle. Chemical leasing strives for a win-win situation. It aims to increase the efficient use of chemicals while reducing the risks of chemicals and protecting human health. It improves the economic and environmental performance of participating companies and enhances their access to new markets. Key elements of successful chemical leasing business models are proper benefit sharing, high-quality standards, and mutual trust between participating companies (UNIDO, 2011).

The shift in product focus to service focused business models pioneered by UNIDO has been labelled with interchangeable terms such as “servitisation”, “product-service systems”, “integrated solutions”, “service infusion”, “tertiarisation” (Lay et al 2010), “servicizing”, “service enhancement”, “service factory” (Tian et al, 2012) and “eco-efficient services” (Goedkoop et al, 1999). Evidence from European manufacturing industry indicates an increasing service intensity starting from mid 1990s (Falk and Peng, 2013).

The focus on the optimization of chemical use and the recognition that it is a specialist, or expert area has led to the evolution of Chemical Management services (CMS). It may be considered as the next step to Chemical Leasing as it involves a strategic, and long-term relationship where the service provider manages the customers’ chemicals and services allied with it. The scope of CMS may ,inter alia, include procurement, inventory management, delivery, disposal, and data management of all the chemicals used in an industrial unit by an expert service provider.

A generalized view which may be applied to the chemical servitization business models is Product-Service Systems (PSS) model. PSS is defined as “a marketable set of products and services capable of jointly fulfilling a user’s need” (Goedkoop, 1999). The opportunities of application for these are endless while the service can be offered in four different modes:

Result-Oriented — Seller sells access to a result that a product generates, Utility-Oriented — Seller sells access to the product for the extent of use, Use-Oriented — Seller sells access to the product over a period of time (e.g., length of use),Product-Oriented — Seller provides the product to the user and sells services to keep the product in use (e.g., access to repair, faulty product replacement). Chemical Leasing may be considered as the result oriented mode.

Chemical Leasing (ChL) and Chemical Management Services (CMS) support in the achievement of multiple SDGs

Sustainable chemicals use and management is enabled through the performance based business model of Chemical leasing (ChL) and the expert management of chemicals across their full life cycle in Chemical Management Services (CMS). The following SDGs may be achieved through the judicious use of ChL and CMS.

-

SDG 3: Good Health and Well-being: Chemical Leasing helps in protecting human health and wellbeing as it strives to reduce the consumption of chemicals while ensuring requisite performance.

-

SDG 6: Clean Water and Sanitation: Reduction in use of chemicals in industrial processes as well as increased recovery directly leads to cleaner water and better sanitation.

-

SDG 9: Industry, Innovation, and Infrastructure: The focus on performance and reduction in consumption promotes sustainable industrial practices and cultivates innovation in chemical management. As a combined result infrastructure becomes robust and resilient.

-

SDG 12: Responsible Consumption and Production: The very focus of Chemical leasing is on the optimum use of chemicals for a required performance. It ,thus, inculcates sustainable consumption and production practices.

-

SDG 13: Climate Action: Its focus on efficient chemical management through a supplier-consumer partnership leads to reduction in emissions and supports climate action.

-

SDG 14: Life Below Water: Reduced discharge and lower chemical presence in discharge ultimately helps in protection and growth of marine ecosystems and supports life below water.

-

SDG 15: Life on Land: Its emphasis on reduction in chemicals used for achieving the requisite output minimizes the impact of industrial processes on terrestrial ecosystems. It in turn helps in promoting sustainable land use and biodiversity.

Possible Business Models for Chemical Servitization

The stakeholders involved in a Chemical Servitization contract are Chemical suppliers (producers and distributors), Chemical users, Equipment suppliers, and Recycling and waste management companies.

Producers and distributors who possess expert knowledge in the efficient and effective use of the chemical substances they manage and the most important players in the Chemical Servitization process. They elevate their role from that of a material supplier to that of a service provider. Users of chemicals may not have the expert knowledge about the chemicals they use, and they will benefit a lot by engaging in the value adding partnership of a Chemical Servitization Model. Since they only pay for the output or benefit realized, they stand to benefit as the processes are optimized. Equipment Suppliers are another essential party in a Chemical Servitization contract as they have the technology and expertise for optimizing the process. It is no doubt a collaborative process. Recycling and waste management companies will provide expertise for proper recycling possibilities and waste management of the chemicals. The incorporation of the recovery and reduction process in the business model will help in developing higher sustainability.

The possible business models are indicated below:

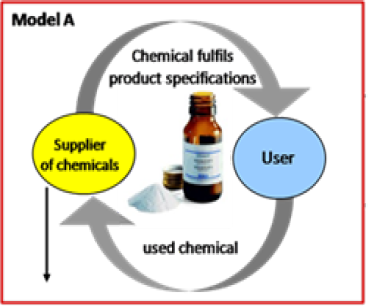

(Source :Economic Features of Chemical Leasing – OECD)

This is the simplest model and involves only the supplier and user. Both partners strive to optimize the use of chemicals and close the material flow to the best extent possible. The user pays for the benefit derived from the chemical in terms of the output or outcome obtained.

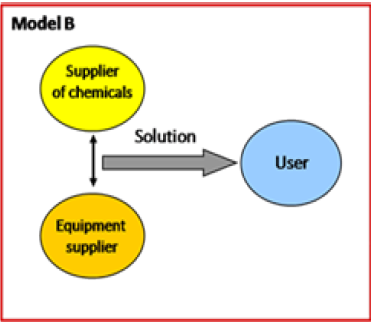

(Source :Economic Features of Chemical Leasing – OECD)

Model B has three partners. The Chemical supplier and equipment supplier work together to provide an optimum solution. The user obtains for the complete solution as a service and pays for it.

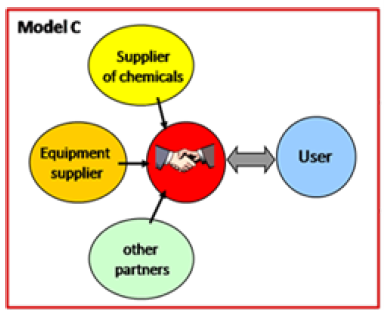

(Source :Economic Features of Chemical Leasing – OECD)

Model C has higher complexity as it brings in yet another specialist, may be a recycling specialist who can recover the chemicals and reduce the effluents. This may call for a more collaborative way of working and normally involves long term commitment of all partners.

Application of Chemical Servitization across industry

Though the application is vast and wide across industries UNIDO had identified some specific application areas where Chemical Leasing can be implemented easily (Low hanging Fruits).

Though most of the above applications are not the core or patented process, there are companies like ECOPETROL, Columbia who have successfully used Chemical Leasing for their processes of Oil dehydration, water purification, and corrosion inhibition. Some of those processes were patented ones.

The Role of Management Accountants in Promoting Chemical Leasing (ChL) and Chemical Management services (CMS)

We would suggest a modified Activity based Costing method which will consider the process based on the functional aspects or the quantity of output being obtained. Such an approach will enable easy comparison between scenarios for implementing the Chemical Leasing Business model.

Suggested steps for modifying ABC for Chemical Leasing:

-

Identify Functional Outputs: Instead of focusing on activities, identify the functional outputs (e.g., units of product cleaned, area coated, volume treated).

-

Assign Costs to Functional Outputs: Allocate costs based on the quantity of functional output rather than the quantity of chemicals used. This means linking costs to the actual output achieved.

-

Incorporate Process Modifications: Consider modifications in the process, such as recovery and recycling, which reduce the quantity of chemicals consumed. Allocate costs based on the efficiency improvements and reduced chemical usage.

-

Cost Drivers: Use cost drivers that are directly related to the functionality and output. For example, the number of units processed, or the area covered.

-

Performance-Based Metrics: Develop performance-based metrics that measure the efficiency and effectiveness of the chemical processes. This can include metrics like chemical usage per unit of output, waste reduction, and energy savings. One of the major challenges will be determining the environmental costs and benefits in monetary terms. It would be advisable follow the guidelines contained in ISO 14007:2019. This standard is applicable across industries and helps in determining costs and benefits associated with the use of specific chemicals from an environmental and sustainability perspective.

-

Continuous Improvement: Implement continuous improvement practices to optimize the use of chemicals and reduce waste. This can be tracked and measured using the modified ABC approach.

Use case - A Degreasing Process

-

Functional Output: Number of units degreased.

-

Cost Drivers: Number of units processed, efficiency of the degreasing process, using unit quantity of the degreasing chemical

-

Cost Allocation: Allocate costs based on the number of units degreased rather than the quantity of degreasing agent used. Environmental costs must be captured as per the guidelines of ISO

-

Process Modifications: Include recovery and recycling processes that reduce the amount of degreasing agent required.

-

By modifying ABC in this way, we can better align the costing method with the principles of Chemical Leasing, focusing on functionality and efficiency rather than just the quantity of chemicals used

Efforts to popularize Chemical Servitization

Efforts of UNIDO and OECD have been noteworthy in promoting Chemical Leasing (ChL). UNIDO and its partner governments have instituted Global Chemical Leasing awards in four categories. They recognize best practices in case studies, public relations, consultancy, and scientific papers. Management Accountants can use their influence in organizations and industrial bodies to further the adoption of this unique method in India and other countries where it is yet to become popular. UNITAR (United Nations Institute for Training and Research) has developed and published Chemical Leasing Toolkit which is specially designed for Small and Medium sizes enterprises (https://smctools-sme.unitar.org/tools_and_methodologies/chemical-leasing-toolkit/).

On a global perspective there are many companies which offer comprehensive Chemical management services, Castrol (Lubricants and surface chemicals), Incora (aerospace and pharmaceuticals), Rinchem (chemical inventory management and safety compliance), Raytheon: Partnered with Haas TCM for CMS and process improvement. In India, equipment manufacturers like boiler manufacturers have progressed to offer Steam as a service. May be more companies will take effective steps to usher in Chemical Servitization on a larger scale.

References

Economic Features of Chemical Leasing : OECD Environment, Health and Safety Publications, Series on Risk Management No. 37

Falk M and Peng F (2013): The increasing service intensity of European manufacturing, The Service Industries Journal, Volume 33, Issue 15-16, 2013.

Goedkoop MJ, van Halen CJG, te Riele HRM, Rommens PJM (1999): Product Service systems, ecological and economic basics. Report prepared for the Dutch ministries of Environment and Economic Affairs.

Joas R (2008): The concept of Chemical Leasing. Chapter 3 of Jakl T, Schwager P (2008).

Lay G (2014): Servitization in Industry. Springer International Publishing, Switzerland.

Tian Y, Jia Y, Sun H, Li D, Yang Y, Alam Malick S (2012): The moderating effect of service capability on the relationship between service delivery and business performance of manufacturing companies, African Journal of Business Management Vol.6 (6), pp. 2169-2180, 15 February 2012.

Title photo courtesy: pexels.com

Copyright © 2025. Rajagiri Business School. All Rights Reserved. Website Designed and Maintained by Intersmart